The Harmer range of roof drainage products is amongst the widest available anywhere in the marketplace. But the variety of drainage conditions encountered in modern refurbishment and new build work means that a standard rainwater outlet will not always be available to address a particular detailing requirement. In such circumstances, a bespoke solution is the only answer.

By combining Harmer technical expertise with the advanced manufacturing capabilities in Alumasc’s workshops, non-standard pipe and rainwater outlet configurations can be manufactured on a bespoke basis to suit the most complicated of design requirements.

The Harmer technical team works alongside Architect and Contractor to produce fully engineered solutions from first concept through to finished product.

We have an extensive portfolio of successful past solutions in situations where a bespoke rainwater drainage design was the only answer. Our innovative, problem-solving specials cover a myriad of applications in which a bespoke design creates a drainage solution in applications that would otherwise be unworkable.

Our special designs have solved problems with overflow, pipework configurations, flow rates, practical constructional issues, problems with the location of pipework, compliance with Building Regulations and conformity with the requirements of bodies such as the National Housebuilding Council (NHBC).

Whatever the drainage problem you face, the Harmer specialist team is here to assist. We work alongside architect and contractor to produce a fully engineered solution from first concept though to finished solution.

Whatever the problem, our expert team evaluates and devises an efficient solution – a unique service that gives designers confidence that all drainage issues are effectively dealt with and any potential problems solved.

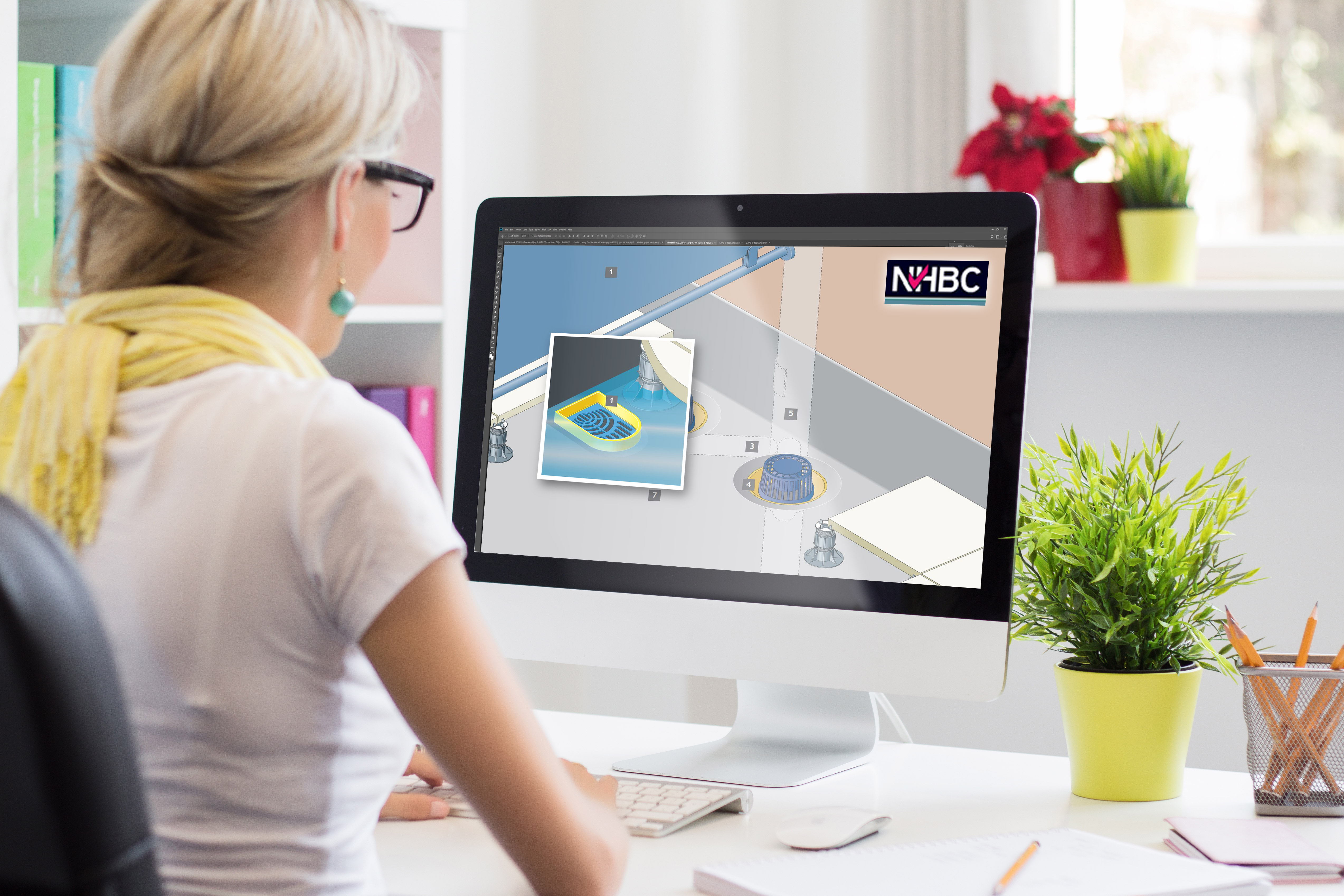

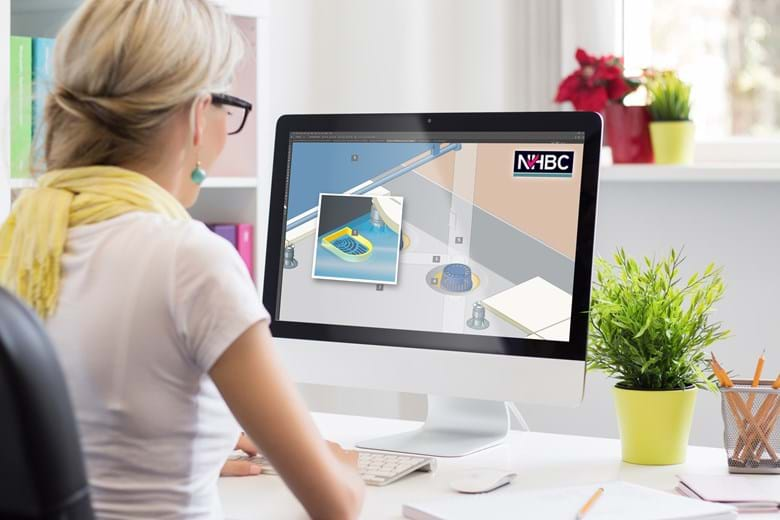

Our bespoke service has provided practical ways of complying with NHBC requirements. Where flat roofs of balconies have an upstand on all sides, NHBC requires provision of an overflow outlet in the event of other outlets becoming blocked.

The Harmer design team has designed a baffle that is factory-welded to the clamping ring of a standard rainwater outlet, creating an overflow outlet that allows water build-up to drain freely before flooding danger level is reached

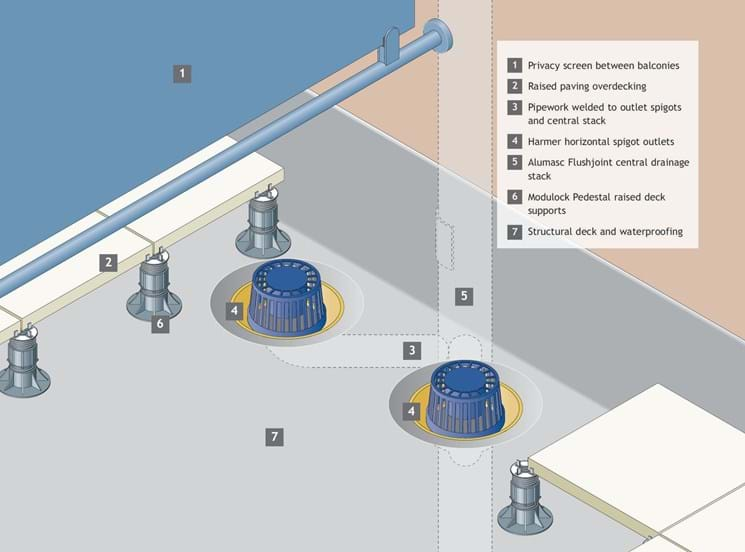

Draining paired balconies to a shared rainwater stack in multi-storey construction

Two Harmer 90 degree horizontal spigot outlets (Code ref 390) welded into a shared rainwater stack. A fully fabricated assembly with rodding access door and connection spigot designed to connect to a ducted rainwater pipe system.

This drainage solution was devised specifically to drain paired balconies in a multi-storey construction. A privacy screen separates two adjacent balconies, which share a rainwater downpipe located within a recess. The downpipe is 110mm in diameter to accommodate a high flow demand from the balconies in the multi-storey arrangement, and also drains water from the flat roof of the building. The rainwater outlets use 75mm diameter pipework, not so much for flow demand but because is it preferable to 50mm pipework, which may be susceptible to blockage. The balconies are overdecked and the outlets are fitted with domical grates that fit within the void between the decking and the structural deck.

Each twin outlet assembly has been manufactured as an individual ‘out-of-the-box’ item, complete with rodding access door and spigot for connection to the principal rainwater stack above and below each balcony.

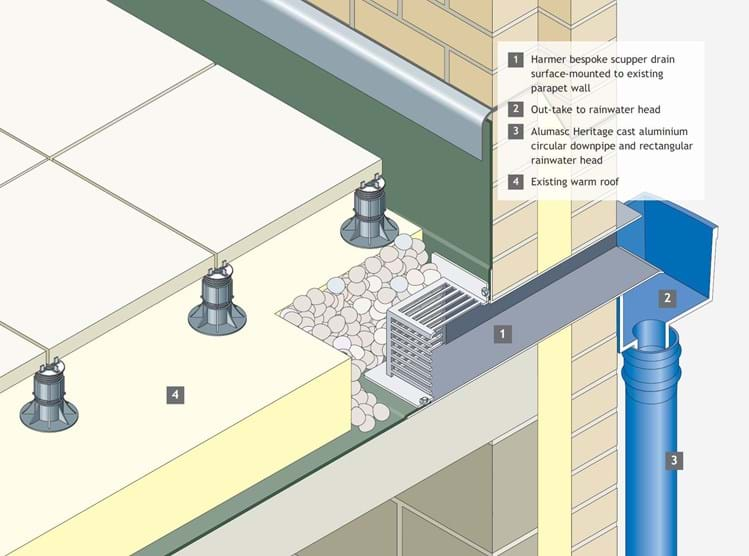

Need for a retro installation of parapet drainage where installing a standard two way-outlet was not feasible fear of exposing

A special scupper drain design with flanged connection to avoid risks associated with disturbing the existing concrete slab.

Several special scupper drain designs were developed for different parapet drainage conditions on the same project. Each scupper drain was carefully sized to meet a required high flow rate.

All the special scupper drains were designed with a generous flange for waterproofing and non-intrusive, flush-mounted installation. This meant that the concrete slab could remain undisturbed, without scabbling, which could reduce cover on the reinforcement.

The scupper drain designs also allowed for fitting of a clamping collar for the waterproof membrane, and a grate.